JEFFER Engineering and Technology Co.,Ltd

JEFFER Engineering Design Co.

|

Product Details:

Payment & Shipping Terms:

|

| Name Of Product: | Construction Glass | Condition: | New |

|---|---|---|---|

| Color: | Clear | Capacity: | 180-300tpd |

| Waranty: | 1 Year | After-sales Service: | Engineers Available To Service Overseas |

| High Light: | 6mm Float Glass Production Line,ISO45001 6mm float glass machine,ODM Float Glass Production Line |

||

6mm Thickness, Construction Float Glass Processing Treatment Equipment

1. Brief Description

The name of float glass is because of the glass liquid floating and forming on a metallic tin liquid surface. By using this forming method, it is not need to overcome the gravity of the glass, it can enlarge the width of the glass, improve the speed of stretch, and increase the capacity and scale of production.

The float glass has a flatness surface, excellent optical performance, no distortions, due to its good quality, the yield float glass can be used for deep processing fabrication.

2. Characteristic

3. Thickness and Application

| Item | Thickness | Application |

| 1 | 2mm, 3mm, 4mm, 5mm, 6mm | Construction |

| Automobile | ||

| 2 | 2mm, 3mm, 5mm, 6mm | Mirror |

| 3 | 8mm, 10mm | Construction |

| 4 | 12mm | Construction |

| 5 | 15mm | Construction |

| 6 | 19mm | Construction |

4. Raw Materials

Main materials are mainly including:

| Silica Sand |

| Dolomite |

| Limestone |

| Feldspar |

| Soda Ash |

| Salt Cake |

| Cullet |

Auxiliary materials as the important raw materials, it mainly includes:

| Clarify Agent |

| Coloring Agent |

| Decolorizing Agent |

| Oxidizing Agent |

| Reducing Agent |

| Combustion Agent |

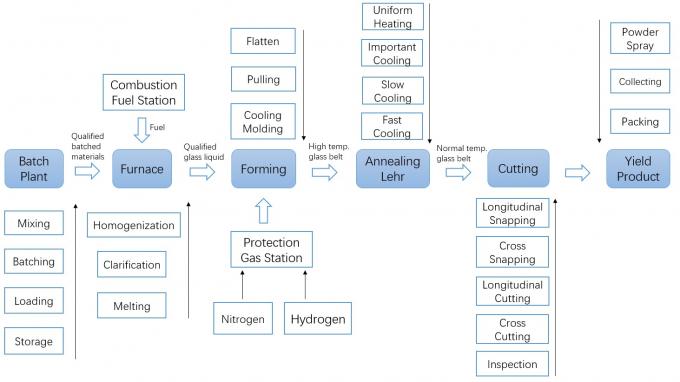

5. Technical Flow Chart of Float Glass Line

6. Main Equipment Description

6.1 Batch Plant

For batching and mixing the raw materials.

6.2 Furance

The melting tank is key part of glass production line, the refractory materials quality is very important.

6.3 Tin Bath

Glass liquid float on the metallic tin, through stretching, forming, polishing and cooling processing, a qualified glass plate is formed and its temperature reduces around 600°C, the transition roller will send the plate to annealing lehr.

6.4.Protection Gas Station

The protection gas station shall operate continuously to produce and supply the required gas for tin bath.

In order to overcome the air and oxygen brought through the entering of the glass liquid and inert gas itself, a center percentage of hydrogen gas shall be added into nitrogen gas.

Besides the good melting efficient, the bright and clean surface of metallic tin is also another important key to produce good float glass product, So, an inert gas or reducing gas to be adopted for a kind of protection gas to prevent the tin from oxidized.

In the upper space of tin bath, it must be full filled with a protection gas.

Normally, Nitrogen gas (N2) and Hydrogen gas (H2) gas are to be used as protection gas. Which is mainly for preventing or reducing the oxidation of metallic tin liquid.

6.5. Annealing Lehr

In glass technology, annealing means to put the glass into the annealing lehr for a certain time or reduce the temperature with a slow speed, so as to no additional permanent stress or temporary stress will produce. Namely, annealing also means a process which will reduce or eliminate the thermal stress of glass.

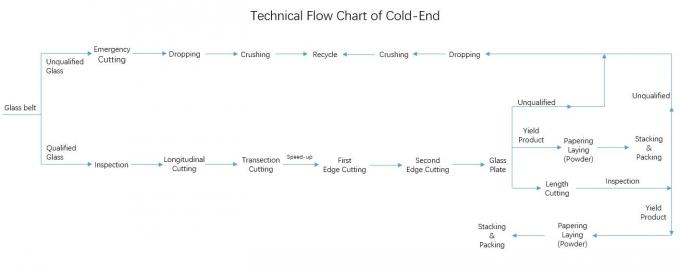

6.6. Colde-end

Contact Person: Ms. Maggie YU

Tel: 86 0 15923299865

Fax: 86-023-6785-3375